Power Transformer Noise and Noise Tests

|

E. Doğan, B. Kekezoğlu

|

Abstract— Voltage level must be raised in order to

deliver the produced energy to the consumption zones with less loss and less

cost. Power transformers used to raise or lower voltage are important parts of

the energy transmission system. Power transformers used in switchgear and power

generation plants stay in human's intensive habitat zones as a result of

expanding cities. Accordingly, noise levels produced by power transformers have

begun more and more important and they have established itself as one of the

research field. In this research, the noise cause on transformers has been

investigated, it's causes has been examined and noise measurement techniques

have been introduced. Examples of transformer noise test results are submitted

and precautions to be taken were discussed for the purpose of decreasing of the

noise which will occurred by transformers.

I.

INTRODUCTION

Transformers

which are the important building blocks of the power system should be designed

and operated considering both electrical parameters and environmental effects.

The noise level of the transformers used especially in urban areas must be at a

level that does not threaten human health. Despite that the occurrence of noise

on the transformer is inevitable.

|

Power

transformers, which perform the function of obtaining the desired voltage

level, allow to right power transfer. In this respect, utilization rate of

power transformers which are indispensable of power systems is gradually

increasing.

Transformers

inherently may form noise depending on certain factors. This situation has

reached such dimensions that affect human health particularly in urban areas. Therefore,

it has become a liability which investigates the cause of the noise in the

transformer and determines preventive actions.

In this study,

factors leading to noise in transformers are described with detail. Standards

related to noise levels have been revealed and noise tests which have been

realized on transformers have been examined in the light of standards. Noise

measurements which occurred on three power transformers are also presented and

interpreted. Solution recommendations related to the subject as a result of the

thesis are presented.

Power transformers enable

optimum power transfer by making intended voltage level obtained in energy

systems. In this respect, transformers’ usage rate which is irreplaceable for

energy systems is gradually increasing.

Transformers

intrinsically can make noise depending upon some factors. This case affects

human health especially in urban areas. For this reason, it has become a

responsibility to search noise reasons and take preventive activities.

In this study, noise

factors in power transformers are explained in details. Noise level standards

are determined and noise tests on transformers are scrutinized in consideration of the standards. Besides,

noise measurements of three different power transformers are presented and

construed. As a result of the thesis study, solution offers about the topic are

presented.

The noise can be

occurred based on load and no-load on power transformers. The incidence cause

of core noise which is known as no-load noise is elastic length changes in the

core resulting from the magnetization. Load noise occurs from vibration

generation of magnetic force caused by load currents on windings, tank walls

and magnetic shield. On the other hand, the noise occurs from fan and pump

which are used for power transformers as cooling equipment should be taken into

account.

Case studies made so far about the noises occurred in the

transformers are listed below.

A.Ilo, B.Weiser,

T.Booth, H. Pfützner[1] have been investigated the effects of geometric

parameters on transformers in their works. B.Weiser and H.Pfützner[2] have been

investigated the relationship between magnetostriction and magnetic forces and

acoustic noise occurring in the transformer core. Also the single-step-lap (SSL)

and multistep-lap (MSL) methods have been compared experimentally. Ishida,

Okabe and Sato[3] have been investigated the effects of clamping pressure and

the material used on three-phased transformer which was made from different

materials packaged by SSL and MSL methods. Teeraphon Phophongviwat[4] have been

investigated the effects of magnetostriction and magnetic forces on vibration

and noise which occur in the transformer's core in his work. And he has been

intended to determine appropriate parameters to explain the relationship

between transformer's core vibration and noise. Girgis, Bernesjö and Anger[5]

have been investigated the characteristics of load noise, the impact of the

load noises on the overall noise, the parameters which effect the load noise

and methods that can reduce noise in the work they have done. Ertl and Voss[6]

have investigated the effect of load harmonics on the noise occurred in

transformer in 2014.

The reasons of the noises in transformers were explained in the

chapter 2 of this work. In chapter 3, it was explained how the noise tests

should be done and examples of noise measurements are presented. The study was

terminated in chapter 4.

II.

POWER

TRANSFORMER NOISES

The transformers used in power systems should be designed as not to

harm human health. Therefore, it is necessary to clarify the harmful noise

level for human health.

Noise levels that

humans are unsuitable were described in TS 9315 ISO 1996-1/T1, TS ISO 1996-2/T1

and ISO 1996-1:2003 standards. The noise level classification was given in

Table I.

TABLE I

Classification of Noise Levels [13]

Noise in The

First Degree ( 30-65 dB(A) )

|

Discomfort,

Getting Bored, Anger, Concentration and Sleep Disturbance

|

Noise in The

Second Degree ( 65-90 dB(A) )

|

Physiological

Noise, Change of Heartbeat, Acceleration of The Respiration, Decreased of

Pressure in The Brain

|

Noise in The

Third Degree ( 90-120 dB(A) )

|

Physiological

Noise, Headache

|

Noise in The

Fourth Degree ( 120-140 dB(A) )

|

Hearing Disorders

|

Noise in The

Fifth Degree (

|

Explosion of The

Eardrum

|

The Power

transformers where used in residential area have to generate noise lower than a

level that affect human health. Transformer noise can be examined under three

headings and these are; “Core Noise”, “Load Noise” and “Fan-Pump Noise”.

A.

Core Noise

“Core Noise” occurs

from voltage. Magnetic forces in core are the cause of magnetostriction and

thus occurs vibration on transformer. Core noise arises from oscillation of

silicon steel sheets. “Core Noise”, generally is seen as the source of dominant

noise. Barely at modern transformers which reduced noise components, were

developed core design. At the modern transformers which are developed core

design, is reduced noise components.

B.

Load Noise

Noise which caused by the current is load noises. The source of the

noise increases proportionally with loading of the transformer. Nowadays harmonic

components increase in the power grid because of the developing power

electronic technologies. As a consequence of that form of the sinusoidal wave

is depraved. Harmonic distortion that occurring higher frequency than the

frequency of the fundamental component, give rise to vibration at transformer

winding. Electro-magnetic forces created by the load current constitute leakage

flux at magnetic shield with winding. And this vibration engenders load noises.

For the development of core design at modern transformers, the source of

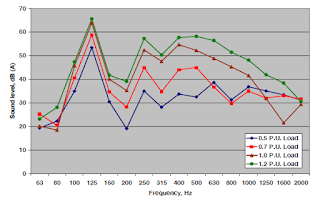

dominant noise is seen as load noise. In figure 1, load noise frequency

spectrum of a power transformer is shown.

Fig. 1 - The Frequency Spectrum of the Load Noise of the Power Transformer

[5]

C.

Fan-Pump Noise

The third factor which is effective on the

transformer noise is fan and pump noise. As known magnetic induction that

occurs between the nucleus and the transformer windings in the core, cause to

rise in the heat level. Because of reaching very high level of heat value, the

transformer needs to cooling system. Fan and pumps are used in power

transformers in order to form the cooling apparatus. This pump and fans which

is used to cool the transformer are effective at transformer noise even if just

a bit. According to J. Pan and others fan noise is characteristically

broad-band in nature. Therefore it influences little at noise problem in around

transformers [7].

In figure 2 it is shown that

core noise (noise occurring in the unloaded condition), noise occurring under

load and the noise made by fan's sound according to a 333 kVA transformer's

load conditions.

Fig. 2 - Sound Level of a Modern

Low Core-Noised Transformer under the Load Conditions [5]

III.

Transformer Noıse Tests

Before commissioning of power transformers the

essential noise tests have to be done. First tests have to be done are listed

below and sample test results are presented.

A.

Measurements of Noise

Consisting of sound pressure and sound

intensity, there are two different measurement methods to evaluate the

transformer noise. In the present study, measurements of sound pressure are

described. In this sound pressure measurements are used type-1 sound level

meter which is in accordance with standard IEC 60651 and calibrated with 5.2

article of ISO 3746[8].

According to this, in the condition of forced cooling system is off

the measurement has to be taken 0.3 meters away from the transformer surface.

And the measurement has to be taken 2 meters away from the transformer if the

cooling systems are on. If the tank height is under 2.5

meters the measurement has to be taken from the half of the total tank height. If the tank height is greater than 2.5 meters then the measurement

has to be taken from total tank height's 1/3 and 2/3 heights.

The microphone must be positioned at the stated height and distance.

In addition, a measurement must be taken from at least six microphones. The

horizontal distance between the microphones mustn't be more than 1 meter.

The transformer's A-weighted sound power level and the total of core

noise and load noise under nominal current and voltage is expressed as L_(WA,SN) equivalence 1[8].

L_(WA,SN)=10lg((10)^(0,1L_(WA,UN) )+(10)^(0,1L_(WA,IN) )) (1)

Nominal current, nominal frequency and A-weighted sound power level

of impedance voltage can be calculated with L_(WA,IN) equivalence 2 [8].

L_(WA,IN)≈39+18lg S_r/S_p

(2)

"S" is the area of measurement surface and measured values

gathered from 0.3 meter can be defined with equivalence 3 [8].

S=1,25hl_m (3)

In here "h"

is for the height of the transformer tank and l_m is defined as measurement environment. 1.25

coefficient is a constant derived from experimental observations. Equivalence 4

is used for measurements gathered from 2 meters away[8].

S=(h+2)l_m (4)

Average background noise is defined in L_bg equivalence 5. M is the number of background

measurement point between 1 and 10. L_bgi, i. is the

background sound pressure level measured at the measurement point [9].

(L_bgA ) ̅=10〖log〗_10 (1/M ∑_(i:1)^M▒〖10〗^(0,1L_bgi ) ) (5)

Unadjusted average sound power level is given in L_pAO equivalence 6. N is the number of measurement

points and L_pAi i. is the sound power level in the measurement

point [9].

(L_pAO ) ̅=10〖log〗_10 (1/N ∑_(i:1)^N▒〖10〗^(0,1L_pAi ) ) (6)

After measurement the

second background measurement should be done. If corrected A-weighted sound

pressure level (L_pA ) ̅ , is given in equation 7 [9].

(L_pA ) ̅=10〖log〗_10 (〖10〗^(0,1(L_pAO ) ̅ )-〖10〗^(0,1(L_bgA ) ̅ ) )-K (7)

Finally the

resulting sound power level L_wA , It is defined in equation 8. S, as square meter surface area

measurements and S_0 is reference area. (1m2) [9].

L_wA=(L_pA ) ̅+10〖log〗_10 S/S_0 (8)

B.

Transformers Noise Test Results

In this study, Noise measurement tests which

performed by Turkish Electricity Transmission Company (TEIAŞ), are submitted.

Noise levels are measured as appropriate to international measurement standard(IEC

6006-10). Measurements are performed by with Brüel&Kjaer 2260.

250 MVA autotransformer noise measurements are

given in table III, IV and this transformer’s excitation voltages are chosen 3.675kV

(%100 ) and 4.293kV

(%110

) and 4.293kV

(%110 ). Test

frequency is 50 Hz, transformer’s tank height is 3,61 m, microphone heights are

1.2 m and 2.41 m at respectively 1/3 and

2/3 height of the tank. Microphones are placed 2 m away from transformer.

Transformer cooling system is OFAF and during measurement 7 fans and 2 pumps

are service.

). Test

frequency is 50 Hz, transformer’s tank height is 3,61 m, microphone heights are

1.2 m and 2.41 m at respectively 1/3 and

2/3 height of the tank. Microphones are placed 2 m away from transformer.

Transformer cooling system is OFAF and during measurement 7 fans and 2 pumps

are service.

TABLE II

Noıse Pressure of Measurement Area [10]

Position

|

Before the Test

|

After the Test

|

Position

|

Before the Test

|

After the Test

|

1

|

48.3

|

47.3

|

6

|

48.7

|

48.2

|

2

|

49.3

|

47.5

|

7

|

47.1

|

48.2

|

3

|

48.2

|

47.6

|

8

|

47.9

|

48.3

|

4

|

47.4

|

48.0

|

9

|

||

5

|

48.6

|

48.8

|

10

|

||

Arithmetic/Average Energy,

|

48.2

|

48.0

|

|||

Noise level of

testing environment in before and after of test is measured.

TABLE III

Noise Pressure Levels in 250 MVA

Autotransformer [10]

Sound Pressure Level,

|

||||||||

Test Voltage: 100%

|

||||||||

MP

|

Height (h)

|

MP

|

Height (h)

|

MP

|

Height (h)

|

|||

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

|||

1

|

67.0

|

66.5

|

16

|

67.0

|

66.5

|

31

|

68.7

|

68.3

|

2

|

66.1

|

67.5

|

17

|

66.5

|

66.5

|

32

|

68.5

|

67.5

|

3

|

65.1

|

66.6

|

18

|

65.4

|

65.2

|

33

|

68.7

|

67.4

|

4

|

65.7

|

65.3

|

19

|

65.7

|

66.3

|

34

|

68.2

|

67.8

|

5

|

66.5

|

65.2

|

20

|

66.9

|

66.4

|

35

|

66.9

|

67.6

|

6

|

65.0

|

67.7

|

21

|

66.6

|

66.3

|

36

|

66.5

|

67.8

|

7

|

66.5

|

65.7

|

22

|

67.6

|

67.0

|

37

|

67.6

|

66.4

|

8

|

66.0

|

66.5

|

23

|

68.1

|

67.1

|

38

|

67.4

|

66.7

|

9

|

68.9

|

69.4

|

24

|

68.0

|

67.2

|

39

|

66.4

|

67.5

|

10

|

66.2

|

69.8

|

25

|

67.6

|

67.0

|

40

|

67.3

|

66.1

|

11

|

66.4

|

66.5

|

26

|

66.9

|

66.1

|

41

|

67.3

|

66.5

|

12

|

67.4

|

67.5

|

27

|

67.6

|

66.7

|

42

|

67.5

|

66.7

|

13

|

68.4

|

65.8

|

28

|

67.6

|

66.1

|

43

|

66.4

|

67.2

|

14

|

65.5

|

66.2

|

29

|

68.6

|

67.2

|

44

|

66.4

|

66.5

|

15

|

66.0

|

65.7

|

30

|

68.0

|

67.5

|

|||

Arithmetic/Average

Energy,

|

67.0 dB(A)

|

|||||||

18.9 dB(A)

|

||||||||

Environmental

Correction, K (must be less than 7 dB)

|

6.7 dB

|

|||||||

Corrected

Average Sound Pressure Level,

|

60.3 dB(A)

|

|||||||

Guaranteed

Sound Pressure Level

|

65.0 dB(A)

|

|||||||

Defined

Peripheral Length

|

44.0

|

|||||||

Area of

the Measurement Surface(OFAF)

|

246.8

|

|||||||

10lg(S/

|

23.9

|

|||||||

Calculated

Average Noise Power Level,

|

84.2 dB(A)

|

|||||||

As shown in Table, there is a difference 18.9

dB(A) between total arithmetic average sound pressure and the arithmetic average

sound pressure of test environment. In this transformer 27PHD090 type 0,27 mm thickness

and 30PH105 type 0,30 mm thickness siliceous sheet metals which high

grain oriented (HGO) are used. The magnetic flux density of the relevant

materials is given as (B8[T]) 1,90-1,91 T. With increasing material's B8 value,

magnetostriction acceleration level tends to decrease. It is related to HGO

material to be used and on the reasons of the high B8 value, autotransformer's

core noise is reduced. However, the reason of the noise occurring in

transformer as I mentioned before , with parameters , in addition it may be

remain at high values of no load harmonic currents. Measured no load current

harmonics are given in Table IV.

TABLE IV

Measured

in 250 MVA Autotransformer, No Load Harmonic Currents [10]

Voltage

(kV)

|

Phase

|

Measured (Harmonics)

|

|||

3.

|

5.

|

7.

|

9.

|

||

3.674

|

a1

|

16.8%

|

17.5%

|

10.0%

|

1.0%

|

b1

|

12.1%

|

15.3%

|

8.1%

|

1.8%

|

|

c1

|

23.7%

|

11.3%

|

7.7%

|

3.0%

|

|

In the case of 250 MVA autotransformer’s test voltage %110  , the noise measurements were made in the same

environmental conditions. In this statement, there is a difference 24.8 dB(A)

between the total arithmetic average of sound pressure and the arithmetic

average sound pressure of ambient as it is seen, in case of increasing the test

voltage, approximately 6 dB(A) increase occurred. The measurement results are given in Table V.

, the noise measurements were made in the same

environmental conditions. In this statement, there is a difference 24.8 dB(A)

between the total arithmetic average of sound pressure and the arithmetic

average sound pressure of ambient as it is seen, in case of increasing the test

voltage, approximately 6 dB(A) increase occurred. The measurement results are given in Table V.

TABLE V

In

the case of 250 MVA autotransformer’s test

voltage %110  , occured noise levels[10]

, occured noise levels[10]

Sound Pressure Level,

|

||||||||

Test Voltage: 110%

|

||||||||

MP

|

Height (h)

|

MP

|

Height (h)

|

MP

|

Height (h)

|

|||

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

|||

1

|

71.5

|

72.9

|

16

|

74.0

|

75.8

|

31

|

71.5

|

72.1

|

2

|

70.3

|

72.1

|

17

|

74.1

|

71.7

|

32

|

72.5

|

73.8

|

3

|

71.7

|

71.6

|

18

|

71.7

|

72.6

|

33

|

72.4

|

72.7

|

4

|

71.1

|

72.6

|

19

|

70.7

|

73.1

|

34

|

72.8

|

72.5

|

5

|

72.4

|

74.2

|

20

|

72.7

|

71.5

|

35

|

71.1

|

76.0

|

6

|

72.0

|

74.4

|

21

|

72.1

|

70.2

|

36

|

70.8

|

72.7

|

7

|

75.0

|

74.5

|

22

|

74.0

|

73.6

|

37

|

72.1

|

72.3

|

8

|

74.6

|

74.3

|

23

|

72.6

|

72.6

|

38

|

73.6

|

70.8

|

9

|

75.7

|

76.9

|

24

|

71.0

|

72.1

|

39

|

73.5

|

73.3

|

10

|

73.6

|

72.9

|

25

|

72.9

|

70.8

|

40

|

71.8

|

70.6

|

11

|

73.8

|

77.9

|

26

|

72.1

|

70.3

|

41

|

70.9

|

72.0

|

12

|

75.0

|

74.6

|

27

|

70.6

|

70.9

|

42

|

72.5

|

70.2

|

13

|

74.0

|

72.8

|

28

|

75.0

|

73.3

|

43

|

71.2

|

75.8

|

14

|

71.8

|

76.5

|

29

|

72.6

|

73.0

|

44

|

71.2

|

73.2

|

15

|

71.5

|

70.6

|

30

|

70.8

|

72.6

|

|||

Arithmetic/Average

Energy,

|

72.9 dB(A)

|

|||||||

24.8 dB(A)

|

||||||||

Environmental

Correction, K (must be less than 7 dB)

|

6.7 dB

|

|||||||

Corrected

Average Sound Pressure Level,

|

66.2 dB(A)

|

|||||||

Guaranteed

Sound Pressure Level

|

70.0 dB(A)

|

|||||||

Calculated

Average Noise Power Level,

|

90.2 dB(A)

|

|||||||

Rated power which was built by TEIAŞ 50 / 62.5

MVA, the rated voltage of 154 / 33.6 kV and a power transformer cooling system

which is called as ONAN, noise level measurements are taken of the 0.3 m and 2 m distances from the ONAN(cooling

system) are given in Table VI and Table VII.

Noise level of environment which made measurements measured 43.5 dB (A).

TABLE VI

Taken

the Noise Levels in 0.3 m Distance [11]

Sound Pressure of Measurement Area:

43.5 dB(A)

|

|||||||||||

Measuring Distance, x: 0.3 m, MP: Measuring Point

|

|||||||||||

MP

|

Height (h)

|

MP

|

Height (h)

|

MP

|

Height (h)

|

||||||

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

||||||

1

|

55.4

|

55.4

|

10

|

56.6

|

57.5

|

18

|

55.9

|

55.1

|

|||

2

|

57.0

|

55.7

|

11

|

56.6

|

54.3

|

19

|

53.8

|

54.5

|

|||

3

|

60.0

|

57.7

|

12

|

55.1

|

57.2

|

20

|

57.3

|

54.6

|

|||

4

|

51.0

|

57.1

|

13

|

57.7

|

57.7

|

21

|

59.8

|

55.3

|

|||

5

|

58.7

|

56.4

|

14

|

59.7

|

57.6

|

22

|

56.2

|

54.5

|

|||

6

|

58.2

|

54.2

|

15

|

59.4

|

57.5

|

23

|

54.0

|

54.9

|

|||

7

|

57.1

|

55.8

|

16

|

58.4

|

57.4

|

24

|

58.0

|

54.8

|

|||

8

|

56.5

|

53.2

|

17

|

59.6

|

55.5

|

25

|

53.2

|

53.0

|

|||

9

|

58.7

|

55.5

|

|||||||||

Arithmetic/Average

Energy,

|

1/3h

|

2/3h

|

|||||||||

57.5 dB(A)

|

55.9 dB(A)

|

||||||||||

Environmental

Correction, K (must be less than 7 dB)

|

2.37 dB

|

||||||||||

Corrected

Average Sound Pressure Level,

|

54.3 dB(A)

|

||||||||||

Guaranteed

Sound Pressure Level

|

60.0 dB(A)

|

||||||||||

Defined

Peripheral Length

|

23.2

|

||||||||||

Area of

the Measurement Surface(OFAF)

|

104.7

|

||||||||||

10lg(S/

|

20.2

|

||||||||||

Calculated

Average Noise Power Level,

|

74.5 dB(A)

|

||||||||||

TABLE VII

Taken

the noise levels in 2 m distance [11]

Sound Pressure of Measurement Area:

43.5 dB(A)

|

||||||||||

Measuring Distance, x: 2 m, MP: Measuring Point

|

||||||||||

MP

|

Height (h)

|

MP

|

Height (h)

|

MP

|

Height (h)

|

|||||

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

(1/3)

|

(2/3)

|

|||||

1

|

63.9

|

61.3

|

14

|

62.4

|

62.8

|

26

|

63.8

|

63.3

|

||

2

|

63.4

|

63.1

|

15

|

62.8

|

63.5

|

27

|

63.1

|

63.3

|

||

3

|

63.4

|

63.4

|

16

|

63.8

|

63.3

|

28

|

63.9

|

61.8

|

||

4

|

63.9

|

63.4

|

17

|

63.5

|

63.4

|

29

|

63.4

|

61.4

|

||

5

|

63.8

|

63.5

|

18

|

63.5

|

63.3

|

30

|

63.0

|

61.0

|

||

6

|

63.7

|

63.8

|

19

|

63.5

|

63.4

|

31

|

62.4

|

62.5

|

||

7

|

63.0

|

62.9

|

20

|

63.3

|

63.8

|

32

|

62.2

|

62.9

|

||

8

|

63.9

|

62.3

|

21

|

63.6

|

63.3

|

33

|

61.9

|

63.1

|

||

9

|

62.9

|

61.6

|

22

|

63.0

|

63.3

|

34

|

62.9

|

63.3

|

||

10

|

62.5

|

61.8

|

23

|

63.1

|

63.4

|

35

|

63.7

|

63.4

|

||

11

|

62.0

|

61.7

|

24

|

63.8

|

63.4

|

36

|

63.3

|

63.5

|

||

12

|

63.4

|

61.5

|

25

|

63.2

|

63.1

|

37

|

63.5

|

63.1

|

||

13

|

62.1

|

61.4

|

||||||||

Arithmetic/Average

Energy,

|

1/3h

|

2/3h

|

||||||||

63.2 dB(A)

|

62.9 dB(A)

|

|||||||||

Environmental

Correction, K (must be less than 7 dB)

|

3.86 dB

|

|||||||||

Corrected

Average Sound Pressure Level,

|

59.2 dB(A)

|

|||||||||

Defined

Peripheral Length

|

36.8

|

|||||||||

Area of

the Measurement Surface(OFAF)

|

206.4

|

|||||||||

10lg(S/

|

23.2

|

|||||||||

Calculated

Average Noise Power Level,

|

82.4 dB(A)

|

|||||||||

IV.

Conclusion

Transformers which are indispensable of power systems are formed on

noise levels should not affect the human health. In this reason, suppression of

noise sources of the transformer constituting the physiological and

psychological effects in humans will play an important role in reducing the

environmental noise. In this study revealed transformer noise sources and

transformer noise measurement methods are described. It was examined and

interpreted noise tests which was given by TEIAŞ.

In the light of detected information, the design

of modern transformers and as a result of the development of materials which is

used core noise (no-load noise) usually ceased to be the dominant noise problem.

Pump and fan noise is not considered as dominant source of noise due to less influence

of noise from no-load condition. Transformer noises' dominant noise source is

usually the load-noise with occurring magnetic leakage flux under load. In this

direction, harmonics which is found in load current must be damped and

transformer mustn’t be overload.

References

[1] A.Ilo, B. Weiser, T. Booth, H. Pfützner,

Influence of Geometric Parameters on the Magnetic Properties of Model

Transformer Cores, 1996

[2] B. Weiser, H. Pfützner, Member, IEEE, and J.

Anger, Relevance of Magnetostriction and Forces for the Generation of Audible

Noise of Transformer Cores, 2000

[3] M. Ishida, S. Okabe, K. Sato, Analysis of

Noise Emitted from Three-Phase-Stacked Transformer Model Core, 1998

[4] Teeraphon Phophongviwat, Wolfson Centre for

Magnetics Cardiff School of Engineering, Investigation of the Influence of

Magnetostriction and Magnetic Forces on Transformer Core Noise and Vibration,

2013

[5] Ramsis S. Girgis, Mats Bernesjö, Jan Anger,

Comprehensive Analysis of Load Noise of Power Transformers

[6] Michael Ertl, Stephan Voss, The Role of Load

Harmonics in Audible Noise of Electrical Transformers, 2014

[7] R.S. Ming, J. Pan, M. P. Norton, S. Wende,

H. Huang, The Sound-Field Characterisation of a Power Transformer, 1999

[8] IEC 60076-10, Power Transformers-Part 10:

Determination of Sound Levels, 2001

[9] Ake Carlson, Jitka Fuhr, Gottfried Schemel,

Franz Wegscheider, Testing of Power Transformers, 2003

[10] TEİAŞ 250 MVA Ototransformatörün Gürültü

Ölçümü, 2012

[11] TEİAŞ 50/62,5 MVA Güç Transformatörünün

Gürültü Ölçümü, 2011

Erdi Dogan was born in Elazıg, Turkey, in

1989. He graduated in electrical and electronic engineering at the Fatih

University, Turkey in 2011. In 2015 he joined Turkish

Electricity Transmission Company(TEİAŞ) in Erzurum, Turkey and he is currently

working as an electrical engineer at the Load Distribution Manager. He is

currently studying master of science in electrical engineering at Yildiz

Technical University, Turkey.

His research interests power

transformes, power transmission system and power quality.

Bedri

Kekezoglu was born in Istanbul, Turkey, in 1982. He

is currently working as an Assistant Professor at the Electrical Engineering

Department of Yildiz Technical University, Turkey.

His research interests include analysis

of power systems, wind energy systems and power quality.

E. Dogan is with Turkish Electricity Transmission Company, Turkey, (corresponding

author to provide phone: +90-0442 242 27 58 e-mail: edoganenerji@ gmail.com).

B. Kekezoglu is with Electrical

Engineering Department, Yildiz Technical University, Istanbul, TURKEY (,

e-mail: bkekez@ yildiz.edu.tr).

Hiç yorum yok:

Yorum Gönder